好用的全自動封膠線,都藏著這些關鍵特質

時間:2025-12-27 來源:http://m.bjrcc.com.cn/ 發布人:昌盛機械

好用的全自動封膠線,都藏著這些關鍵特質

The easy-to-use fully automatic sealing line hides these key characteristics

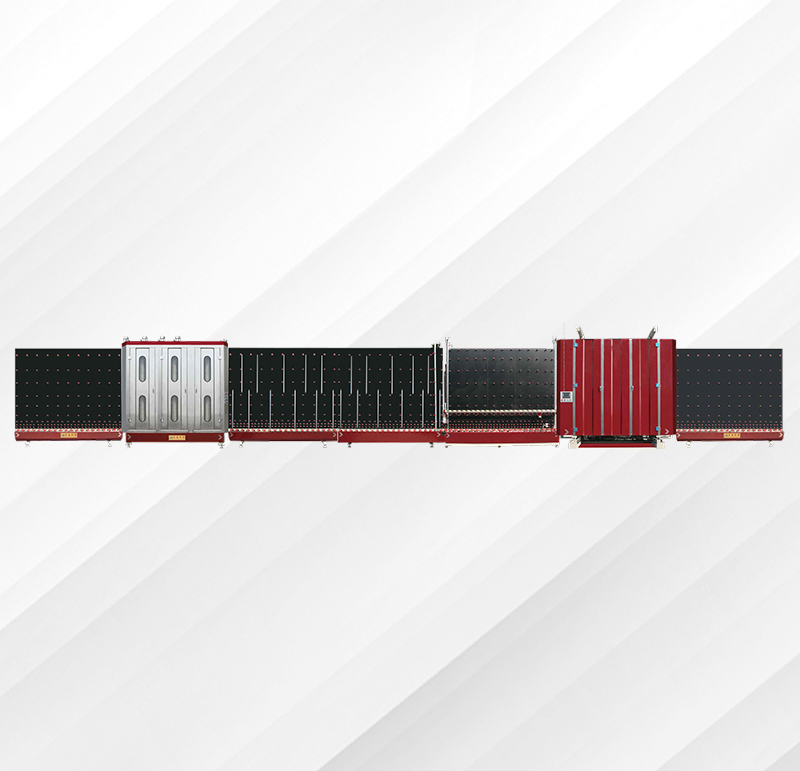

在玻璃深加工、建材制造等領域,全自動封膠線是保障產品密封性、穩定性的核心設備。一款好用的全自動封膠線,不僅能大幅提升生產效率,更能避免因封膠問題導致的產品返工、質量隱患。但很多人對“什么樣的封膠線才靠譜”缺乏清晰認知,今天就從核心配置、適用范圍、性能優勢等維度,帶大家讀懂全自動封膠線的選型關鍵。

In fields such as glass deep processing and building materials manufacturing, fully automatic sealing lines are the core equipment to ensure product sealing and stability. A user-friendly fully automatic sealing line that not only greatly improves production efficiency, but also avoids product rework and quality hazards caused by sealing problems. But many people lack a clear understanding of what kind of sealing line is reliable. Today, from the dimensions of core configuration, scope of application, performance advantages, etc., we will take you to understand the key selection of fully automatic sealing line.

優質的核心元器件,是全自動封膠線“經久耐用”的基礎。對工業設備而言,電氣元件和電纜線就像“神經和血管”,直接決定設備的使用壽命和運行穩定性。好用的全自動封膠線,大多會采用進口品牌電氣元件及電纜線。這類元器件經過嚴苛的工業場景驗證,抗干擾能力強、故障率低,能適應長時間連續作業的需求,有效減少設備停機維修的頻率,降低企業的運維成本。反觀一些劣質設備,為壓縮成本選用廉價元器件,不僅容易出現短路、信號中斷等問題,還可能因元件損壞導致封膠流程中斷,影響生產進度。

High quality core components are the foundation for the durability of fully automatic sealing wires. For industrial equipment, electrical components and cables are like "nerves and blood vessels", directly determining the service life and operational stability of the equipment. Most of the user-friendly fully automatic sealing wires use imported electrical components and cables. These types of components have been rigorously tested in industrial scenarios, with strong anti-interference capabilities and low failure rates. They can adapt to the needs of long-term continuous operation, effectively reducing the frequency of equipment downtime and maintenance, and lowering the operation and maintenance costs of enterprises. On the other hand, for some inferior equipment, choosing cheap components to compress costs not only leads to problems such as short circuits and signal interruptions, but also may cause interruptions in the sealing process due to component damage, affecting production progress.

適用范圍的靈活性,是衡量封膠線實用性的重要指標。不同行業、不同產品對玻璃加工的尺寸需求差異極大,一款好用的全自動封膠線,必須具備廣泛的適配能力。以行業主流的優質設備為例,其可加工的玻璃尺寸跨度極大,最小能精準適配260mm×300mm的小規格玻璃,最大則可覆蓋2500mm×4000mm的大尺寸玻璃。這種寬范圍的適配能力,能讓企業無需為不同尺寸的產品單獨配備設備,既節省了車間空間,又降低了前期投入成本,尤其適合產品類型豐富的加工企業。

The flexibility of the scope of application is an important indicator for measuring the practicality of the sealing line. The size requirements for glass processing vary greatly among different industries and products. A user-friendly fully automatic sealing line must have extensive adaptability. Taking the mainstream high-quality equipment in the industry as an example, it can process glass with a wide range of sizes. The smallest can accurately adapt to small-sized glass of 260mm × 300mm, and the largest can cover large-sized glass of 2500mm × 4000mm. This wide range of adaptability allows enterprises to avoid the need to equip separate equipment for products of different sizes, saving workshop space and reducing initial investment costs, especially suitable for processing enterprises with diverse product types.

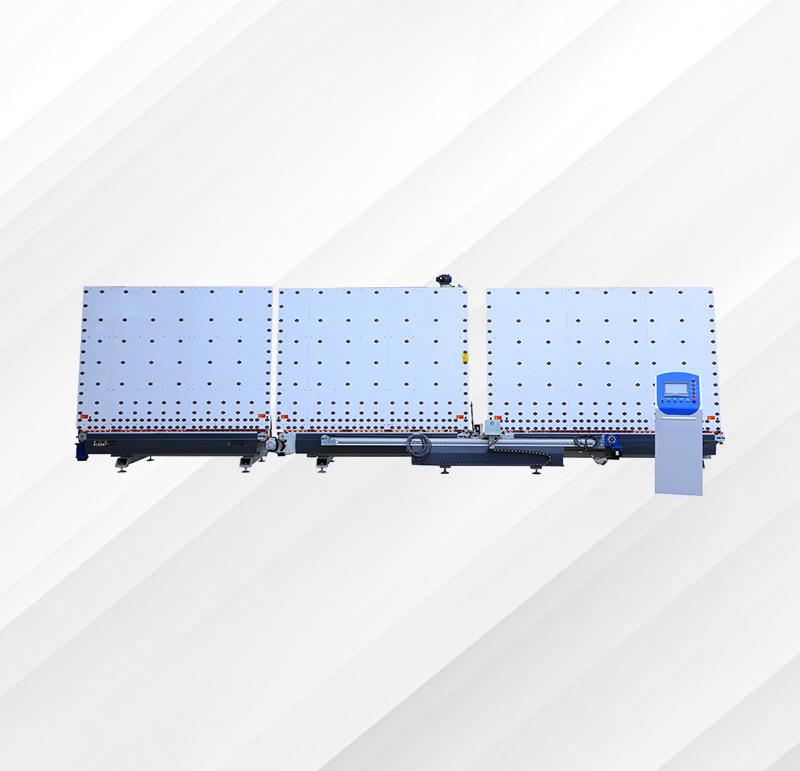

穩定高效的供膠與驅動系統,是封膠質量的核心保障。封膠效果的好壞,直接取決于供膠的穩定性和驅動的精準度。好用的全自動封膠線普遍采用雙增壓雙供膠系統,這種設計能確保供膠過程連續、穩定,避免出現斷膠、溢膠等問題,同時還能根據不同材質的玻璃和膠料類型,靈活調節供膠壓力,適配多樣化的加工需求。在驅動系統上,優質設備會選用高規格的伺服系統,比如行業認可度極高的安川7系伺服。這類伺服系統的運算速度極快,能精準響應設備的各項操作指令,配合精密的機械結構,實現對封膠軌跡、出膠量的精準控制。

A stable and efficient glue supply and drive system is the core guarantee of sealing quality. The quality of the sealing effect directly depends on the stability of the adhesive supply and the precision of the driving. The commonly used fully automatic sealing line adopts a dual pressure and dual supply system, which ensures a continuous and stable glue supply process, avoiding problems such as glue breakage and overflow. At the same time, it can flexibly adjust the glue supply pressure according to different types of glass and glue materials, and adapt to diverse processing needs. In the drive system, high-quality equipment will choose high specification servo systems, such as the highly recognized Yaskawa 7 series servo in the industry. This type of servo system has extremely fast computing speed and can accurately respond to various operating instructions of the equipment. With precise mechanical structure, it can achieve precise control of the sealing trajectory and dispensing volume.

出膠的精確度和運行穩定性,是全自動封膠線的核心競爭力。對玻璃加工而言,封膠不僅要“封得住”,更要“封得勻”。優質封膠線憑借精準的伺服驅動和穩定的供膠系統,能將出膠量的誤差控制在極小范圍,確保膠線均勻、平整,既保證了產品的密封性,又提升了外觀美觀度。同時,穩定的運行性能能讓設備在長時間連續作業中保持一致的加工精度,避免因設備波動導致的封膠質量參差不齊。這一點對批量生產的企業尤為重要,能有效提升產品的合格率,增強企業的市場競爭力。

The precision and operational stability of adhesive production are the core competitiveness of fully automatic sealing lines. For glass processing, sealing glue should not only be able to "seal", but also "seal evenly". With precise servo drive and stable glue supply system, high-quality sealing lines can control the error of glue output within a very small range, ensuring that the glue line is uniform and flat, which not only ensures the sealing performance of the product, but also improves the appearance aesthetics. At the same time, stable operational performance can ensure consistent processing accuracy of the equipment during long-term continuous operation, avoiding uneven sealing quality caused by equipment fluctuations. This is particularly important for enterprises engaged in mass production, as it can effectively improve product qualification rates and enhance their market competitiveness.

綜上,一款好用的全自動封膠線,并非單一參數的優勝,而是核心元器件、適配范圍、供膠驅動系統、精度穩定性等多方面的綜合達標。對于企業而言,選擇符合這些特質的封膠線,不僅是提升生產效率的選擇,更是保障產品質量、降低長期運營成本的關鍵。在工業自動化日益普及的今天,讀懂這些核心特質,才能更好地選擇適合自身需求的設備,讓自動化設備真正成為企業發展的助力。

In summary, a user-friendly fully automatic sealing line is not a single parameter advantage, but rather a comprehensive standard that meets multiple aspects such as core components, adaptation range, adhesive supply drive system, and precision stability. For enterprises, choosing a sealing line that meets these characteristics is not only a choice to improve production efficiency, but also a key to ensuring product quality and reducing long-term operating costs. In today's increasingly popular industrial automation, understanding these core characteristics is necessary to better choose equipment that suits one's own needs and make automation equipment truly a driving force for enterprise development.

本文由 全自動封膠線 友情奉獻.更多有關的知識請點擊 http://m.bjrcc.com.cn/ 真誠的態度.為您提供為全面的服務.更多有關的知識我們將會陸續向大家奉獻.敬請期待.

This article is a friendly contribution from the fully automatic sealing line For more related knowledge, please click http://m.bjrcc.com.cn/ Sincere attitude To provide you with comprehensive services We will gradually contribute more relevant knowledge to everyone Coming soon.

- 中空生產線封膠線機頭立柱不平?這樣調整,封膠均勻不返工 2026/01/05

- 中空玻璃加工設備卡殼?液壓站不起壓?卡閥問題這樣解決超省心 2025/12/31

- 全自動封膠線卡殼?貼鋁條后玻璃不走、報警?這樣解決超簡單 2025/12/31

- 冬天中空玻璃生產線出輪子灰印?這些日常難題解決辦法請收好 2025/12/30

- 全自動封膠線的“智能眼”——LOW-E識別儀,守護封膠質量的關鍵 2025/12/30

- 好用的全自動封膠線,都藏著這些關鍵特質 2025/12/27

- 雙組份打膠機,中空玻璃第二道密封的“精準調控專家” 2025/12/27

- 別讓施工疏漏毀了成品!中空玻璃質量問題,多與這幾點及加工設備相關 2025/12/26

- 中空玻璃生產線90度邊有波浪?生產時常見問題排查指南 2025/12/26

- 丁基膠擠出溫度適宜卻不粘基材?丁基膠涂布機應用攻略來了 2025/12/25

當前位置:

當前位置:

產品分類Product categories

產品分類Product categories

聯系我們Contact us

聯系我們Contact us