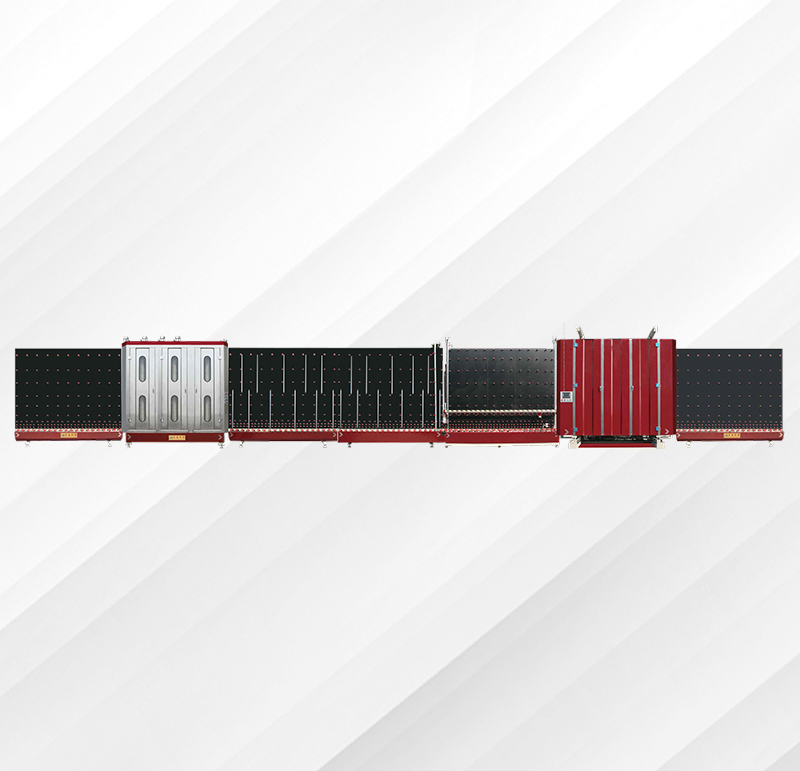

合片+充氣+板壓一步到位!中空玻璃生產線效率品質雙飆升

時間:2025-12-23 來源:http://m.bjrcc.com.cn/ 發布人:昌盛機械

合片+充氣+板壓一步到位!中空玻璃生產線效率品質雙飆升

Folding+inflation+plate pressing in one step! The efficiency and quality of the insulated glass production line have skyrocketed

在傳統中空玻璃生產流程中,合片、充氣、板壓往往分屬不同工位,工件需在各設備間反復轉運。這不僅耗費大量人工與時間,更易引發合片偏移、充氣泄漏、板壓不均等問題——合片歪了影響密封間隙,充氣漏了削弱保溫效果,板壓松了導致后期脫膠,最終造成返工損耗與品質隱患。而合片+充氣+板壓一體化的中空玻璃生產線,通過工序整合與智能控制,將三大核心環節濃縮為一步,從根本上解決了傳統生產的痛點,實現效率與品質的雙重提升。

In the traditional production process of insulating glass, lamination, inflation, and plate pressing are often assigned to different workstations, and the workpieces need to be repeatedly transported between various equipment. This not only consumes a lot of manpower and time, but also easily leads to problems such as misalignment, inflation leakage, and uneven board pressure - misalignment of the lamination affects the sealing gap, inflation leakage weakens the insulation effect, loose board pressure leads to later delamination, and ultimately causes rework losses and quality hazards. The integrated production line of laminated glass, inflatable glass, and laminated glass concentrates the three core processes into one step through process integration and intelligent control, fundamentally solving the pain points of traditional production and achieving a dual improvement in efficiency and quality.

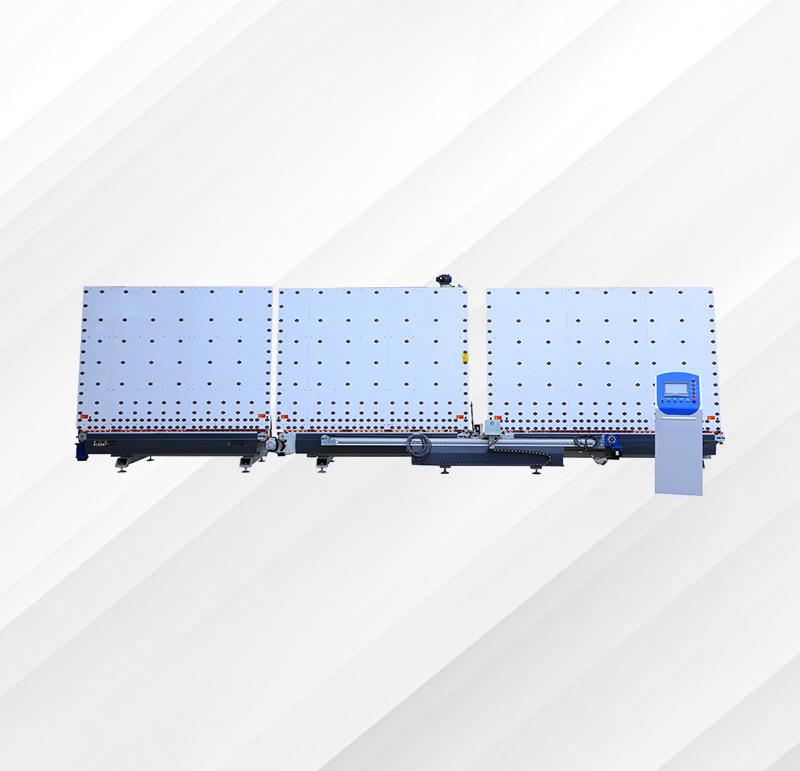

一體化生產線的核心優勢,首先體現在合片的精準穩定性上。設備搭載數控定位系統與紅外對齊裝置,玻璃送入后無需人工干預,即可自動完成邊緣找正與鋁條卡槽精準卡合,合片誤差嚴格控制在≤0.3mm以內,精度較傳統分開式設備提升15倍。無論是常規尺寸的家裝玻璃,還是3米以上的大規格幕墻玻璃,都能實現均勻貼合,避免了“一邊寬一邊窄”的偏差。這種高標準的合片精度,為后續充氣與板壓工序奠定了基礎,也讓下游封膠環節更順暢,減少了因間隙不均導致的密封隱患。

The core advantage of an integrated production line is first reflected in the precision and stability of the lamination process. The equipment is equipped with a CNC positioning system and an infrared alignment device. After the glass is fed in, it can automatically align the edges and accurately fit the aluminum strip slot without manual intervention. The fitting error is strictly controlled within ≤ 0.3mm, and the accuracy is 15 times higher than that of traditional separate equipment. Whether it is regular sized home decoration glass or large-sized curtain wall glass over 3 meters, uniform bonding can be achieved, avoiding the deviation of "one side wide and one side narrow". This high standard of lamination accuracy lays the foundation for subsequent inflation and plate pressing processes, and also makes downstream sealing processes smoother, reducing sealing hazards caused by uneven gaps.

合片與充氣同步進行,是一體化生產線的另一大亮點。傳統生產中,合片后轉運至充氣工位的過程中,易因密封不嚴導致空氣滲入,影響惰性氣體填充效果。而一體化設備在合片完成的瞬間,即可啟動智能惰性氣體控壓系統,精準控制充氣量與壓力,使氣體均勻填充至中空腔體內,填充率輕松達到90%以上,遠超行業85%的平均標準。同時,系統會實時檢測密封性,一旦發現漏點便立即報警,杜絕“充了白充”的無效作業。充足且均勻的惰性氣體填充,讓中空玻璃的保溫、隔音性能顯著提升,即便面對高端建筑的嚴苛要求也能輕松滿足。

Simultaneous merging and inflation is another highlight of the integrated production line. In traditional production, during the process of transferring the laminated sheet to the inflation station, air infiltration is easily caused by poor sealing, which affects the filling effect of inert gas. At the moment of completion of lamination, the integrated equipment can activate the intelligent inert gas pressure control system, accurately control the inflation volume and pressure, and evenly fill the gas into the hollow cavity, with a filling rate of easily over 90%, far exceeding the industry average standard of 85%. At the same time, the system will detect the sealing in real time, and once a leak is found, it will immediately sound an alarm to prevent ineffective operations of "white filling". Adequate and uniform inert gas filling significantly improves the insulation and sound insulation performance of insulated glass, making it easy to meet even the stringent requirements of high-end buildings.

板壓環節的智能適配設計,進一步保障了成品穩定性。一體化生產線采用分段式加壓技術,可根據玻璃厚度、尺寸靈活調整壓力參數:針對薄玻璃采用輕壓模式,避免受力過大導致崩邊;針對厚玻璃或大規格玻璃則加大壓力,確保鋁條與玻璃緊密貼合。壓力均勻覆蓋整個玻璃表面,讓丁基膠充分延展,將玻璃、鋁條牢牢粘合為一體,有效避免了傳統板壓“局部受力不均”導致的松動問題。經實測,采用該設備生產的中空玻璃,密封壽命較傳統工藝延長至少5年,漏風漏水的返工率大幅降低。

The intelligent adaptive design of the plate pressing process further ensures the stability of the finished product. The integrated production line adopts segmented pressure technology, which can flexibly adjust the pressure parameters according to the thickness and size of the glass. For thin glass, a light pressure mode is adopted to avoid edge breakage caused by excessive force; For thick or large-sized glass, increase the pressure to ensure a tight fit between the aluminum strip and the glass. The pressure evenly covers the entire surface of the glass, allowing the butyl rubber to fully extend and firmly bond the glass and aluminum strips together, effectively avoiding the loosening problem caused by traditional board pressing due to uneven local stress. Through actual testing, it has been found that the sealing life of insulated glass produced using this equipment is extended by at least 5 years compared to traditional processes, and the rework rate for air and water leakage is significantly reduced.

更值得關注的是,這款一體化生產線能與整條中空玻璃生產流程無縫銜接。前道清洗后的玻璃可直接送入設備,完成合片、充氣、板壓一體化處理后,再通過傳送帶自動送往下游封膠工位,無需人工中途搬運轉運。這種全流程聯動設計,讓生產效率較傳統分開操作提升30%,單班產能可多產200平中空玻璃,同時減少3名人工投入,顯著降低了運營成本。

More noteworthy is that this integrated production line can seamlessly integrate with the entire production process of insulating glass. After the previous cleaning, the glass can be directly sent to the equipment for integrated processing of lamination, inflation, and plate pressing, and then automatically transported to the downstream sealing station through a conveyor belt, without the need for manual intermediate handling and transportation. This full process linkage design increases production efficiency by 30% compared to traditional separate operations. A single shift can produce an additional 200 square meters of insulated glass, while reducing the labor input by 3 people, significantly reducing operating costs.

作為專注中空玻璃設備的廠家,該生產線還支持定制化適配——可根據玻璃廠的產能需求、常用規格,靈活調整設備參數,適配從常規尺寸到特殊規格的各類玻璃生產。后期維護方面,廠家提供24小時響應服務,及時解決設備運行中的問題,確保生產線穩定運轉。

As a manufacturer specializing in insulated glass equipment, this production line also supports customized adaptation - the equipment parameters can be flexibly adjusted according to the production capacity requirements and common specifications of the glass factory, adapting to various glass production from conventional sizes to special specifications. In terms of post maintenance, the manufacturer provides 24-hour response service to promptly solve equipment operation problems and ensure stable operation of the production line.

對于追求提質增效的玻璃廠而言,合片+充氣+板壓一體化的中空玻璃生產線,不僅是工序的簡單整合,更是生產模式的升級。它以精準合片為基礎、高效充氣為核心、穩定板壓為保障,同時兼顧效率與品質,既解決了傳統生產的諸多痛點,又能滿足高端訂單的品質要求,成為玻璃廠提升市場競爭力的關鍵裝備。

For glass factories that pursue quality and efficiency improvement, the integrated production line of laminated, inflated, and laminated insulating glass is not only a simple integration of processes, but also an upgrade of production mode. It is based on precise lamination, with efficient inflation as the core and stable plate pressure as the guarantee, while balancing efficiency and quality. It not only solves many pain points in traditional production, but also meets the quality requirements of high-end orders, becoming a key equipment for glass factories to enhance market competitiveness.

本文由 中空玻璃生產線 友情奉獻.更多有關的知識請點擊 http://m.bjrcc.com.cn/ 真誠的態度.為您提供為全面的服務.更多有關的知識我們將會陸續向大家奉獻.敬請期待.

This article is a friendly contribution from the insulating glass production line For more related knowledge, please click http://m.bjrcc.com.cn/ Sincere attitude To provide you with comprehensive services We will gradually contribute more relevant knowledge to everyone Coming soon.

- 中空生產線封膠線機頭立柱不平?這樣調整,封膠均勻不返工 2026/01/05

- 中空玻璃加工設備卡殼?液壓站不起壓?卡閥問題這樣解決超省心 2025/12/31

- 全自動封膠線卡殼?貼鋁條后玻璃不走、報警?這樣解決超簡單 2025/12/31

- 冬天中空玻璃生產線出輪子灰印?這些日常難題解決辦法請收好 2025/12/30

- 全自動封膠線的“智能眼”——LOW-E識別儀,守護封膠質量的關鍵 2025/12/30

- 好用的全自動封膠線,都藏著這些關鍵特質 2025/12/27

- 雙組份打膠機,中空玻璃第二道密封的“精準調控專家” 2025/12/27

- 別讓施工疏漏毀了成品!中空玻璃質量問題,多與這幾點及加工設備相關 2025/12/26

- 中空玻璃生產線90度邊有波浪?生產時常見問題排查指南 2025/12/26

- 丁基膠擠出溫度適宜卻不粘基材?丁基膠涂布機應用攻略來了 2025/12/25

當前位置:

當前位置:

產品分類Product categories

產品分類Product categories

聯系我們Contact us

聯系我們Contact us