1分鐘看懂全自動中空玻璃生產線!全程不用人工搬太爽了

時間:2025-12-18 來源:http://m.bjrcc.com.cn/ 發布人:昌盛機械

1分鐘看懂全自動中空玻璃生產線!全程不用人工搬太爽了

Understand the fully automatic insulated glass production line in 1 minute! It's so enjoyable to not have to manually move the entire process

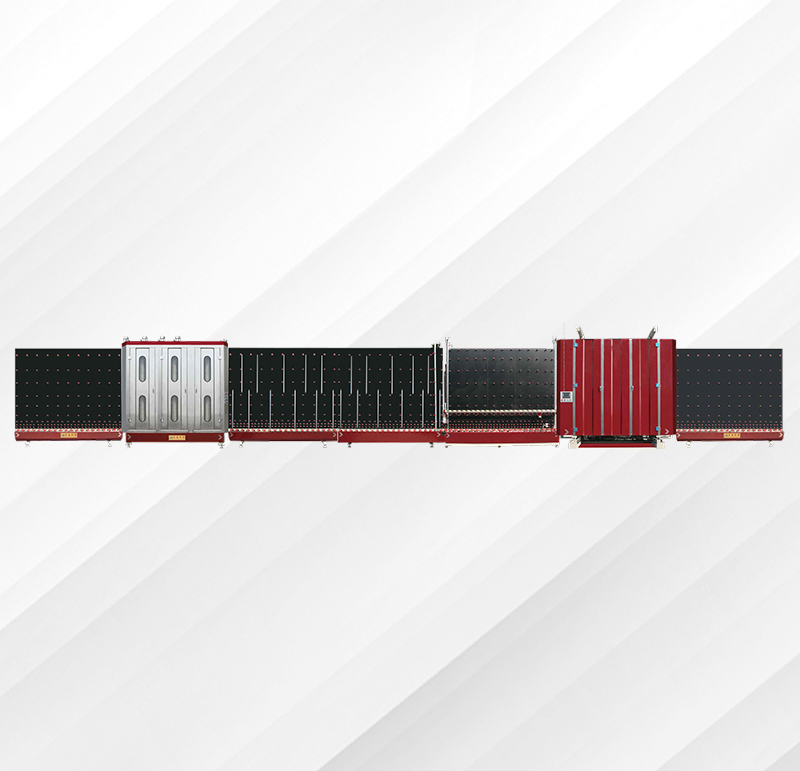

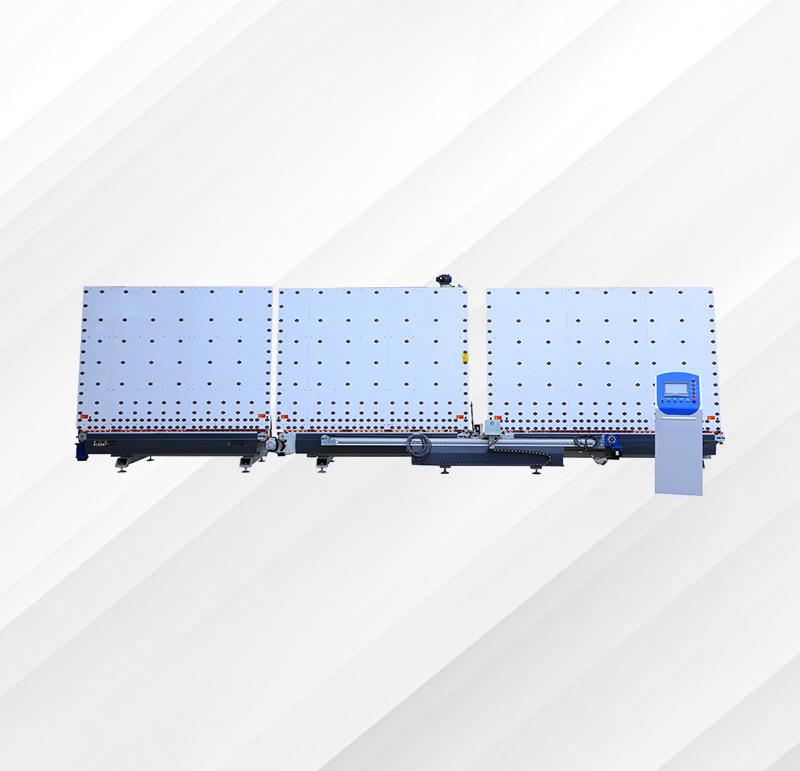

咱玻璃廠的工人都懂,以前做中空玻璃有多折騰:幾塊重玻璃得兩三個人扛著上料,稍不留神就磕碎;合片時蹲在地上對齊,眼睛都看酸了還歪歪扭扭;封膠全靠手藝,膠線時粗時細,氣泡斷點常見,后期漏風漏水全是麻煩。但現在有了全自動中空玻璃生產線,這些苦日子徹底結束了!從玻璃上料到成品下線,全程不用人工搬一下,一個視頻就能看清絲滑作業,源頭廠家實拍,真的太省心了!

The workers in our glass factory all understand how much trouble it used to be when making insulated glass: a few heavy glass pieces had to be carried and loaded by two or three people, and they could be easily broken if they were not careful; Squatting on the ground to align during filming, my eyes were sore and crooked; Sealing relies entirely on craftsmanship. The glue line can be thick or thin, with common bubble breaks and later air and water leaks, all of which are troublesome. But now with the fully automated insulated glass production line, these tough days are completely over! From the glass to the finished product, there is no need for manual movement throughout the entire process. You can see the smooth operation in one video, and the manufacturer takes real photos from the source. It's really worry free!

先說說最讓人驚喜的上片環節,再也不用工人扛玻璃跑了!機械臂跟有“眼睛”似的,自動抓取玻璃精準上料,定位準得很,不會磕碰到玻璃邊緣,既省了人力,又減少了玻璃破碎的損耗。以前上一塊大玻璃得兩個人配合,累得滿頭大汗還怕出意外,現在機械臂幾分鐘就能搞定一批,工人只需要在旁邊看著,輕松多了。

Let's talk about the most surprising part of the film release, no more workers have to carry the glass and run away! The robotic arm is like an "eye" that automatically grasps the glass for precise feeding, with accurate positioning and no collision with the glass edge, saving manpower and reducing the loss of glass breakage. Previously, it required two people to work together on a large piece of glass, sweating profusely and fearing accidents. Now, the robotic arm can handle a batch in just a few minutes, and workers only need to watch from the side, making it much easier.

上料后玻璃直接進清洗倉,高壓水流帶著清洗劑猛沖,同時熱風同步吹干,洗完的玻璃表面干干凈凈,沒有一點水印和雜質,直接就能送往下一環節。以前人工清洗不僅費水,還總有些角落洗不到,烘干不徹底還會影響后續合片密封,現在機器清洗又快又干凈,一步到位不耽誤事。

After loading, the glass is directly fed into the cleaning chamber. The high-pressure water flow carries the cleaning agent and rushes vigorously, while the hot air synchronously blows dry. The cleaned glass surface is clean, without any watermarks or impurities, and can be directly sent to the next stage. Previously, manual cleaning not only required water, but also some corners could not be cleaned thoroughly, and incomplete drying could affect the subsequent sealing of the film. Now, machine cleaning is fast and clean, and it can be done in one step without delay.

合片定位是個技術活,以前人工對齊全靠經驗,玻璃間隔忽寬忽窄,影響成品質量。這臺生產線能自動識別玻璃尺寸,按預設參數精準合片,間隔均勻得像用尺子量過一樣,比人工對齊精準10倍不止。合片后直接進入封膠環節,這可是中空玻璃的核心--雙膠頭同步作業,沿著玻璃邊緣勻速打膠,膠線粗細一致,沒有一點氣泡和斷點,密封性能直接達標,客戶驗收一次就能過,不用返工。

Joint positioning is a technical task. In the past, manual alignment relied entirely on experience, and the glass spacing fluctuated, affecting the quality of the finished product. This production line can automatically recognize the size of glass, accurately fit the pieces according to preset parameters, and have even intervals as if measured with a ruler, which is more than 10 times more accurate than manual alignment. After lamination, it directly enters the sealing process, which is the core of insulated glass - double glue head synchronous operation. Glue is evenly applied along the edge of the glass, with consistent thickness of the glue line, no bubbles or breakpoints, and the sealing performance meets the standard directly. Customers can pass the inspection once without rework.

最后成品下線也超順暢,封膠完成后,傳送帶自動把成品送出來,還能碼放得整整齊齊,全程不用人工中途干預。一條生產線頂得上3個老工人的工作量,以前8小時累得夠嗆才做幾百平米,現在效率翻倍,還能保證每塊玻璃的品質一致,再也不用擔心“忙中出錯”。

The final finished product is also smoothly offline. After the sealing is completed, the conveyor belt automatically sends out the finished product, and it can be neatly stacked without manual intervention throughout the process. A production line can handle the workload of three old workers. In the past, it used to take 8 hours to work hard and only produce a few hundred square meters. Now, the efficiency has doubled and the quality of each piece of glass can be guaranteed to be consistent. You no longer have to worry about making mistakes while busy.

更貼心的是,這臺設備能適配不同尺寸的玻璃生產,不管是小批量定制的異形玻璃,還是大批量趕單的常規尺寸,都能精準調整參數,不用頻繁換模具。作為專業中空玻璃設備廠家,從研發到生產全流程把控,設備耐用性強,工業場景長期高強度運行也靠譜。

What's even more considerate is that this device can adapt to glass production of different sizes, whether it's customized irregular glass in small batches or conventional sizes in large quantities, it can accurately adjust parameters without frequent mold changes. As a professional manufacturer of insulated glass equipment, we control the entire process from research and development to production. Our equipment has strong durability and is reliable for long-term high-intensity operation in industrial scenarios.

現在玻璃行業競爭這么卷,誰能省人力、提效率、保品質,誰就能站穩腳跟。這臺全自動中空玻璃生產線,不僅解決了人工搬玻璃累、合片不準、封膠差的老難題,還能幫廠家節省人力成本、減少損耗,小批量定制和大批量趕單都能扛住。想知道這條線到底能省多少成本?看看源頭廠家的實拍演示就知道,絕對是玻璃廠升級改造的好幫手! 1分鐘看懂全自動中空玻璃生產線!全程不用人工搬太爽了

The competition in the glass industry is so fierce now, whoever can save manpower, improve efficiency, and ensure quality will be able to stand firm. This fully automatic insulated glass production line not only solves the old problems of manual glass moving, inaccurate lamination, and poor sealing, but also helps manufacturers save labor costs and reduce losses. It can withstand small batch customization and large batch order rushing. Do you want to know how much cost this line can save? Just take a look at the real-life demonstration from the original manufacturer, and you will know that it is definitely a good helper for upgrading and renovating glass factories! Understand the fully automatic insulated glass production line in 1 minute! It's so enjoyable to not have to manually move the entire process

咱玻璃廠的工人都懂,以前做中空玻璃有多折騰:幾塊重玻璃得兩三個人扛著上料,稍不留神就磕碎;合片時蹲在地上對齊,眼睛都看酸了還歪歪扭扭;封膠全靠手藝,膠線時粗時細,氣泡斷點常見,后期漏風漏水全是麻煩。但現在有了全自動中空玻璃生產線,這些苦日子徹底結束了!從玻璃上料到成品下線,全程不用人工搬一下,一個視頻就能看清絲滑作業,源頭廠家實拍,真的太省心了!

The workers in our glass factory all understand how much trouble it used to be when making insulated glass: a few heavy glass pieces had to be carried and loaded by two or three people, and they could be easily broken if they were not careful; Squatting on the ground to align during filming, my eyes were sore and crooked; Sealing relies entirely on craftsmanship. The glue line can be thick or thin, with common bubble breaks and later air and water leaks, all of which are troublesome. But now with the fully automated insulated glass production line, these tough days are completely over! From the glass to the finished product, there is no need for manual movement throughout the entire process. You can see the smooth operation in one video, and the manufacturer takes real photos from the source. It's really worry free!

先說說最讓人驚喜的上片環節,再也不用工人扛玻璃跑了!機械臂跟有“眼睛”似的,自動抓取玻璃精準上料,定位準得很,不會磕碰到玻璃邊緣,既省了人力,又減少了玻璃破碎的損耗。以前上一塊大玻璃得兩個人配合,累得滿頭大汗還怕出意外,現在機械臂幾分鐘就能搞定一批,工人只需要在旁邊看著,輕松多了。

Let's talk about the most surprising part of the film release, no more workers have to carry the glass and run away! The robotic arm is like an "eye" that automatically grasps the glass for precise feeding, with accurate positioning and no collision with the glass edge, saving manpower and reducing the loss of glass breakage. Previously, it required two people to work together on a large piece of glass, sweating profusely and fearing accidents. Now, the robotic arm can handle a batch in just a few minutes, and workers only need to watch from the side, making it much easier.

上料后玻璃直接進清洗倉,高壓水流帶著清洗劑猛沖,同時熱風同步吹干,洗完的玻璃表面干干凈凈,沒有一點水印和雜質,直接就能送往下一環節。以前人工清洗不僅費水,還總有些角落洗不到,烘干不徹底還會影響后續合片密封,現在機器清洗又快又干凈,一步到位不耽誤事。

After loading, the glass is directly fed into the cleaning chamber. The high-pressure water flow carries the cleaning agent and rushes vigorously, while the hot air synchronously blows dry. The cleaned glass surface is clean, without any watermarks or impurities, and can be directly sent to the next stage. Previously, manual cleaning not only required water, but also some corners could not be cleaned thoroughly, and incomplete drying could affect the subsequent sealing of the film. Now, machine cleaning is fast and clean, and it can be done in one step without delay.

合片定位是個技術活,以前人工對齊全靠經驗,玻璃間隔忽寬忽窄,影響成品質量。這臺生產線能自動識別玻璃尺寸,按預設參數精準合片,間隔均勻得像用尺子量過一樣,比人工對齊精準10倍不止。合片后直接進入封膠環節,這可是中空玻璃的核心--雙膠頭同步作業,沿著玻璃邊緣勻速打膠,膠線粗細一致,沒有一點氣泡和斷點,密封性能直接達標,客戶驗收一次就能過,不用返工。

Joint positioning is a technical task. In the past, manual alignment relied entirely on experience, and the glass spacing fluctuated, affecting the quality of the finished product. This production line can automatically recognize the size of glass, accurately fit the pieces according to preset parameters, and have even intervals as if measured with a ruler, which is more than 10 times more accurate than manual alignment. After lamination, it directly enters the sealing process, which is the core of insulated glass - double glue head synchronous operation. Glue is evenly applied along the edge of the glass, with consistent thickness of the glue line, no bubbles or breakpoints, and the sealing performance meets the standard directly. Customers can pass the inspection once without rework.

最后成品下線也超順暢,封膠完成后,傳送帶自動把成品送出來,還能碼放得整整齊齊,全程不用人工中途干預。一條生產線頂得上3個老工人的工作量,以前8小時累得夠嗆才做幾百平米,現在效率翻倍,還能保證每塊玻璃的品質一致,再也不用擔心“忙中出錯”。

The final finished product is also smoothly offline. After the sealing is completed, the conveyor belt automatically sends out the finished product, and it can be neatly stacked without manual intervention throughout the process. A production line can handle the workload of three old workers. In the past, it used to take 8 hours to work hard and only produce a few hundred square meters. Now, the efficiency has doubled and the quality of each piece of glass can be guaranteed to be consistent. You no longer have to worry about making mistakes while busy.

更貼心的是,這臺設備能適配不同尺寸的玻璃生產,不管是小批量定制的異形玻璃,還是大批量趕單的常規尺寸,都能精準調整參數,不用頻繁換模具。作為專業中空玻璃設備廠家,從研發到生產全流程把控,設備耐用性強,工業場景長期高強度運行也靠譜。

What's even more considerate is that this device can adapt to glass production of different sizes, whether it's customized irregular glass in small batches or conventional sizes in large quantities, it can accurately adjust parameters without frequent mold changes. As a professional manufacturer of insulated glass equipment, we control the entire process from research and development to production. Our equipment has strong durability and is reliable for long-term high-intensity operation in industrial scenarios.

現在玻璃行業競爭這么卷,誰能省人力、提效率、保品質,誰就能站穩腳跟。這臺全自動中空玻璃生產線,不僅解決了人工搬玻璃累、合片不準、封膠差的老難題,還能幫廠家節省人力成本、減少損耗,小批量定制和大批量趕單都能扛住。想知道這條線到底能省多少成本?看看源頭廠家的實拍演示就知道,絕對是玻璃廠升級改造的好幫手!

The competition in the glass industry is so fierce now, whoever can save manpower, improve efficiency, and ensure quality will be able to stand firm. This fully automatic insulated glass production line not only solves the old problems of manual glass moving, inaccurate lamination, and poor sealing, but also helps manufacturers save labor costs and reduce losses. It can withstand small batch customization and large batch order rushing. Do you want to know how much cost this line can save? Just take a look at the real-life demonstration from the original manufacturer, and you will know that it is definitely a good helper for upgrading and renovating glass factories!

本文由 中空玻璃生產線 友情奉獻.更多有關的知識請點擊 http://m.bjrcc.com.cn/ 真誠的態度.為您提供為全面的服務.更多有關的知識我們將會陸續向大家奉獻.敬請期待.

This article is a friendly contribution from the insulating glass production line For more related knowledge, please click http://m.bjrcc.com.cn/ Sincere attitude To provide you with comprehensive services We will gradually contribute more relevant knowledge to everyone Coming soon.

- 中空玻璃加工設備板壓段卡殼?輪子走玻璃不走?這樣排查超高效 2026/01/10

- 中空生產線封膠線機頭立柱不平?這樣調整,封膠均勻不返工 2026/01/05

- 中空玻璃加工設備卡殼?液壓站不起壓?卡閥問題這樣解決超省心 2025/12/31

- 全自動封膠線卡殼?貼鋁條后玻璃不走、報警?這樣解決超簡單 2025/12/31

- 冬天中空玻璃生產線出輪子灰印?這些日常難題解決辦法請收好 2025/12/30

- 全自動封膠線的“智能眼”——LOW-E識別儀,守護封膠質量的關鍵 2025/12/30

- 好用的全自動封膠線,都藏著這些關鍵特質 2025/12/27

- 雙組份打膠機,中空玻璃第二道密封的“精準調控專家” 2025/12/27

- 別讓施工疏漏毀了成品!中空玻璃質量問題,多與這幾點及加工設備相關 2025/12/26

- 中空玻璃生產線90度邊有波浪?生產時常見問題排查指南 2025/12/26

當前位置:

當前位置:

產品分類Product categories

產品分類Product categories

聯系我們Contact us

聯系我們Contact us