全自動封膠線使用過程中有哪些要注意的地方?

時間:2025-06-11 來源:http://m.bjrcc.com.cn/ 發布人:昌盛機械

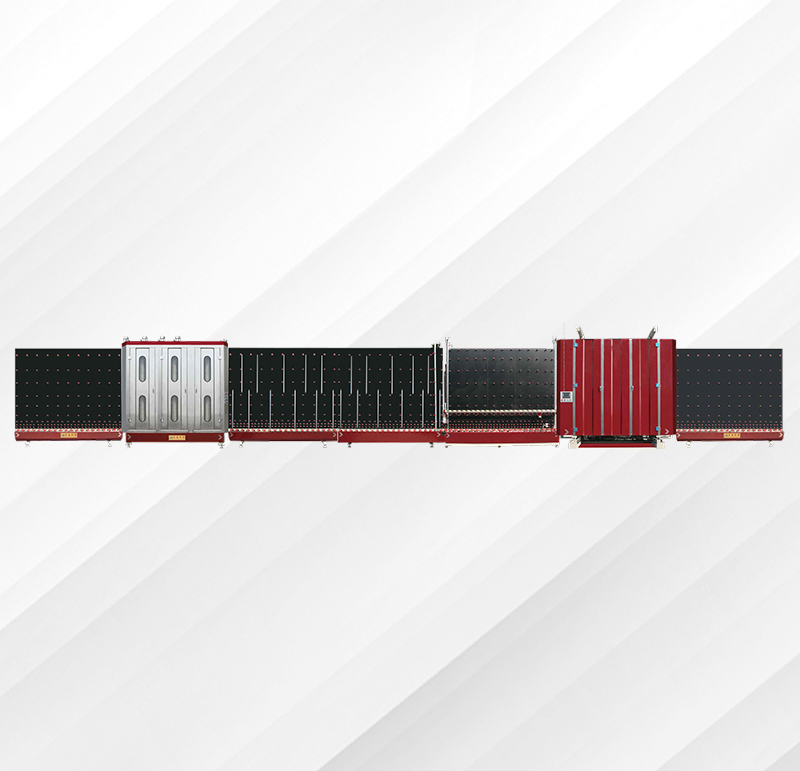

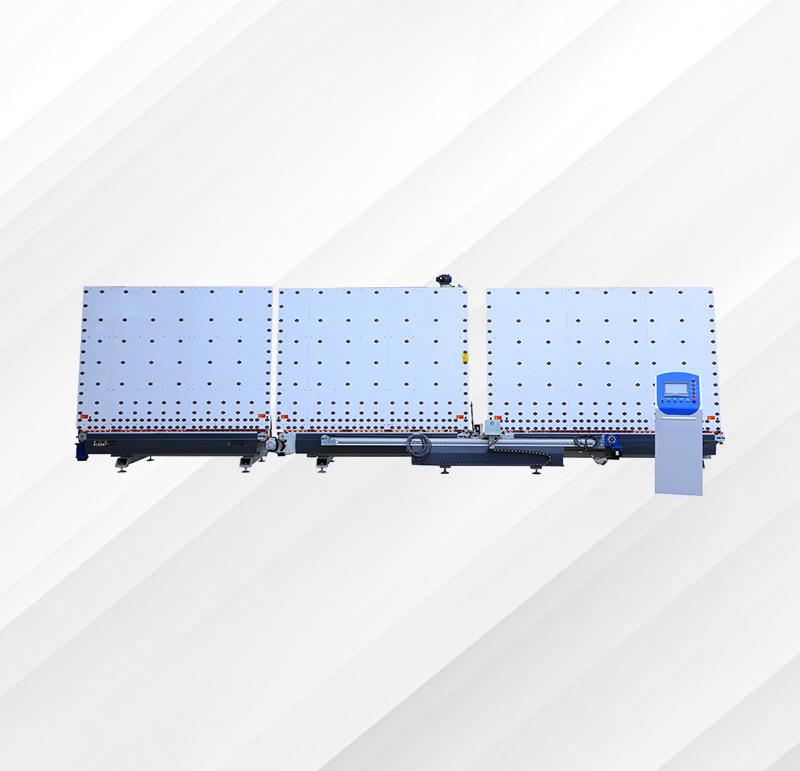

全自動封膠線作為現代制造業的關鍵設備,廣泛應用于電子、汽車、新能源等領域,其穩定運行直接影響產品質量與生產效率。在使用過程中,需從設備操作、工藝控制、安全防護及維護保養四個維度構建標準化流程,以實現高效、安全的封膠作業。

As a key equipment in modern manufacturing, fully automatic sealing lines are widely used in fields such as electronics, automobiles, and new energy. Their stable operation directly affects product quality and production efficiency. During use, standardized processes need to be established from four dimensions: equipment operation, process control, safety protection, and maintenance to achieve efficient and safe sealing operations.

操作前準備:設備檢查與環境確認

Preparation before operation: equipment inspection and environmental confirmation

設備空載試運行:啟動前需進行5-10分鐘空載測試,觀察輸送帶、點膠閥、固化爐等模塊運轉是否平穩,確認無異常振動或噪音。某電子廠案例顯示,未執行空載測試曾導致點膠閥卡滯,造成批量產品返工。

Equipment no-load trial operation: Before starting, a 5-10 minute no-load test is required to observe whether the conveyor belt, dispensing valve, curing furnace and other modules are running smoothly, and confirm that there are no abnormal vibrations or noises. A case study from an electronics factory shows that failure to perform no-load testing resulted in sticking of the dispensing valve, leading to rework of a batch of products.

環境參數校準:檢查車間溫濕度是否符合設備要求,通常需控制在20-25℃、相對濕度40%-60%。某精密儀器制造商實踐表明,環境波動超出范圍會導致膠水黏度變化,影響點膠精度。

Environmental parameter calibration: Check whether the temperature and humidity in the workshop meet the equipment requirements, usually controlled at 20-25 ℃ and relative humidity of 40% -60%. Practice by a precision instrument manufacturer has shown that environmental fluctuations beyond the range can cause changes in adhesive viscosity, affecting dispensing accuracy.

人員防護裝備:操作人員需佩戴防靜電手套、護目鏡及呼吸防護裝置,避免膠水接觸皮膚或吸入揮發性氣體。

Personnel protective equipment: Operators are required to wear anti-static gloves, goggles, and respiratory protection devices to prevent glue from coming into contact with the skin or inhaling volatile gases.

操作過程控制:參數優化與過程監控

Operational Process Control: Parameter Optimization and Process Monitoring

膠水參數匹配:根據膠水類型(如UV膠、環氧樹脂)設置固化能量、點膠壓力及針頭規格。某光伏企業測試發現,UV膠固化能量不足會導致粘接強度下降,而過度曝光則可能引發基材黃變。

Glue parameter matching: Set the curing energy, dispensing pressure, and needle specifications based on the type of glue (such as UV glue, epoxy resin). A photovoltaic company found through testing that insufficient curing energy of UV glue can lead to a decrease in bonding strength, while excessive exposure may cause yellowing of the substrate.

軌跡編程驗證:通過離線編程軟件模擬點膠路徑,重點檢查拐角過渡、Z軸抬升等細節。某汽車電子廠商案例中,未優化的軌跡程序導致線纜端子膠水溢出,引發短路故障。

Trajectory programming verification: Simulate the dispensing path through offline programming software, focusing on checking details such as corner transitions and Z-axis lifting. In a case study of an automotive electronics manufacturer, an unoptimized trajectory program resulted in glue overflow from cable terminals, causing a short circuit fault.

首件檢驗制度:連續生產前需制作3-5件首件,進行拉力測試、外觀檢查及尺寸量測。某消費電子工廠實施該制度后,不良品流出率降低。

First article inspection system: Before continuous production, 3-5 first articles need to be made for tensile testing, visual inspection, and dimensional measurement. After the implementation of this system in a certain consumer electronics factory, the outflow rate of defective products decreased.

安全防護:電氣與機械風險管控

Safety Protection: Electrical and Mechanical Risk Management

急停裝置可達性:確保設備控制面板及關鍵位置急停按鈕無遮擋,某家電企業曾因急停按鈕被物料遮擋,導致事故響應延遲。

Accessibility of emergency stop device: Ensure that the emergency stop button on the equipment control panel and key positions is unobstructed. A certain household appliance company once delayed the response to an accident due to the emergency stop button being obstructed by materials.

安全光柵有效性:定期檢測安全光柵發射端與接收端對射精度,避免人員誤入危險區域。某機器人集成商數據顯示,失效的安全光柵使設備碰撞風險提升。

Safety grating effectiveness: Regularly check the ejaculation degree between the transmitting and receiving ends of the safety grating to prevent personnel from entering dangerous areas by mistake. According to data from a robot integrator, the malfunctioning safety grating increases the risk of equipment collision.

接地與絕緣檢測:使用萬用表每月檢查設備外殼接地電阻,確保其小于4Ω,防止靜電積累引發火災或電擊事故。

Grounding and insulation testing: Use a multimeter to check the grounding resistance of the equipment casing every month, ensuring that it is less than 4 Ω, to prevent static electricity accumulation from causing fire or electric shock accidents.

維護保養:預防性維護與耗材管理

Maintenance and upkeep: preventive maintenance and consumables management

點膠閥清潔周期:根據膠水固化特性制定清洗計劃,溶劑型膠水需每日清洗,UV膠可延長至每周。某醫療器械廠商因未及時清洗導致閥體堵塞,造成生產線停機。

Glue valve cleaning cycle: Develop a cleaning plan based on the curing characteristics of the glue. Solvent based glue needs to be cleaned daily, while UV glue can be extended to weekly cleaning. A medical device manufacturer's production line was shut down due to valve body blockage caused by failure to clean in a timely manner.

輸送帶張力校準:每季度使用張力計檢測同步帶張力,偏差超過10%需調整,避免傳動失步影響點膠位置精度。

Conveyor belt tension calibration: Use a tension meter to detect the tension of the synchronous belt every quarter. If the deviation exceeds 10%, it needs to be adjusted to avoid the transmission being out of step and affecting the accuracy of the dispensing position.

濾芯更換標準:固化爐進風口高效過濾器壓差超過500Pa時必須更換,某新能源電池企業曾因過濾失效導致膠水碳化,污染整個烘道。

Filter replacement standard: When the pressure difference of the high-efficiency filter at the inlet of the curing furnace exceeds 500Pa, it must be replaced. A new energy battery company once caused glue carbonization due to filtration failure, polluting the entire drying oven.

異常處理:故障診斷與應急方案

Exception Handling: Fault Diagnosis and Emergency Response Plan

膠水斷流檢測:配置液位傳感器與壓力監控,當膠量低于閾值或壓力突變時自動停機并報警。某3C電子廠通過該功能避免空打導致的基材損傷。

Glue Cut off Detection: Equipped with a liquid level sensor and pressure monitoring, it will automatically shut down and sound an alarm when the glue amount is below the threshold or when the pressure suddenly changes. A certain 3C electronics factory uses this function to avoid substrate damage caused by blank printing.

固化不良追溯:建立批次管理系統,當檢測到固化不足時,可快速定位同批次產品并啟動返工流程。某LED封裝企業應用后,不良品隔離效率提升。

Curing defect traceability: Establish a batch management system, which can quickly locate products from the same batch and initiate rework processes when insufficient curing is detected. After being applied by a certain LED packaging enterprise, the isolation efficiency of defective products has been improved.

數據備份機制:每日生產結束后導出工藝參數及設備日志,避免程序丟失或數據篡改。某自動化公司案例顯示,未備份數據導致故障復現耗時增加。

Data backup mechanism: Export process parameters and equipment logs after daily production to avoid program loss or data tampering. A case study of an automation company shows that failure to backup data increases the time required for fault reproduction.

全自動封膠線的安全高效運行需構建“預防性維護-精準控制-快速響應”的管理體系。通過操作前檢查、參數動態優化、安全裝置驗證及定期保養,可顯著降低設備故障率與不良品產生。隨著工業物聯網技術的融入,未來封膠線將實現遠程診斷與自適應調節,進一步推動智能制造的深化應用。

The safe and efficient operation of the fully automatic sealing line requires the establishment of a management system of "preventive maintenance precise control rapid response". By conducting pre operation checks, dynamically optimizing parameters, verifying safety devices, and performing regular maintenance, the equipment failure rate and the production of defective products can be significantly reduced. With the integration of industrial Internet of Things technology, the future sealing line will achieve remote diagnosis and adaptive adjustment, further promoting the deepening application of intelligent manufacturing.

本文由全自動封膠線友情奉獻.更多有關的知識請點擊:http://m.bjrcc.com.cn我們將會對您提出的疑問進行詳細的解答,歡迎您登錄網站留言.

This article is a friendly contribution from glass coating machine equipment For more information, please click: http://m.bjrcc.com.cn We will provide detailed answers to your questions. You are welcome to log in to our website and leave a message

- 雙組份打膠機旋轉伺服報警810?這樣解決快速恢復生產 2026/01/16

- 中空玻璃加工設備:打膠機機頭升降鏈條松動?這樣調節精準又牢固 2026/01/14

- 中空玻璃生產線合片段橫梁調平指南:小誤差別忽視,這樣調精準又省心 2026/01/12

- 中空玻璃加工設備的合片段橫梁高低不平?這樣調,合片精準不跑偏 2026/01/11

- 中空玻璃加工設備板壓段卡殼?輪子走玻璃不走?這樣排查超高效 2026/01/10

- 中空生產線封膠線機頭立柱不平?這樣調整,封膠均勻不返工 2026/01/05

- 中空玻璃加工設備卡殼?液壓站不起壓?卡閥問題這樣解決超省心 2025/12/31

- 全自動封膠線卡殼?貼鋁條后玻璃不走、報警?這樣解決超簡單 2025/12/31

- 冬天中空玻璃生產線出輪子灰印?這些日常難題解決辦法請收好 2025/12/30

- 全自動封膠線的“智能眼”——LOW-E識別儀,守護封膠質量的關鍵 2025/12/30

當前位置:

當前位置:

產品分類Product categories

產品分類Product categories

聯系我們Contact us

聯系我們Contact us