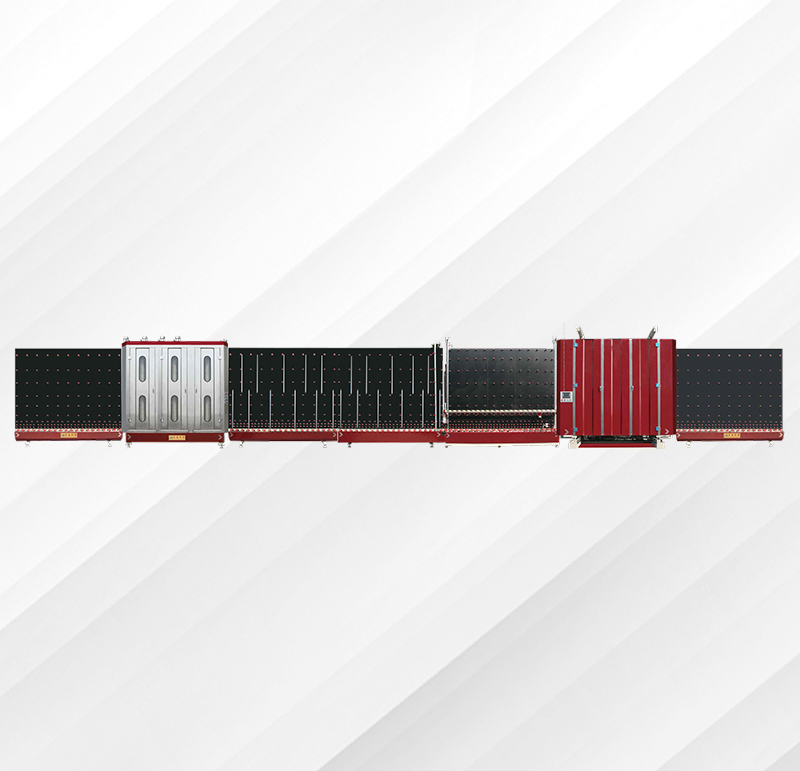

中空玻璃生產線的結構組成

時間:2024-05-21 來源:http://m.bjrcc.com.cn/ 發布人:昌盛機械

中空玻璃生產線是玻璃深加工設備的一種,主要用來加工制作中空玻璃,玻璃原片切割后進入中空生產線主要經過清洗、干燥、制作間隔框、充干燥劑、第一道密封(涂丁基膠)、檢查、放框合片、壓片、第二道密封(聚硫膠或硅酮膠)、下片,所加工出來的產品質量較高,加工速度很快。

Hollow glass production line is a type of glass deep processing equipment, mainly used to process and produce hollow glass. After cutting the original glass, it enters the hollow production line and is mainly cleaned, dried, made into spacer frames, filled with desiccant, first sealed (coated with butyl adhesive), inspected, framed and laminated, pressed, second sealed (polysulfide or silicone adhesive), and cut. The processed product has high quality and fast processing speed.

中空玻璃生產線主要有四段:入料段、清洗干燥段、檢查段和合片段。

The hollow glass production line mainly consists of four sections: feeding section, cleaning and drying section, inspection section, and assembly section.

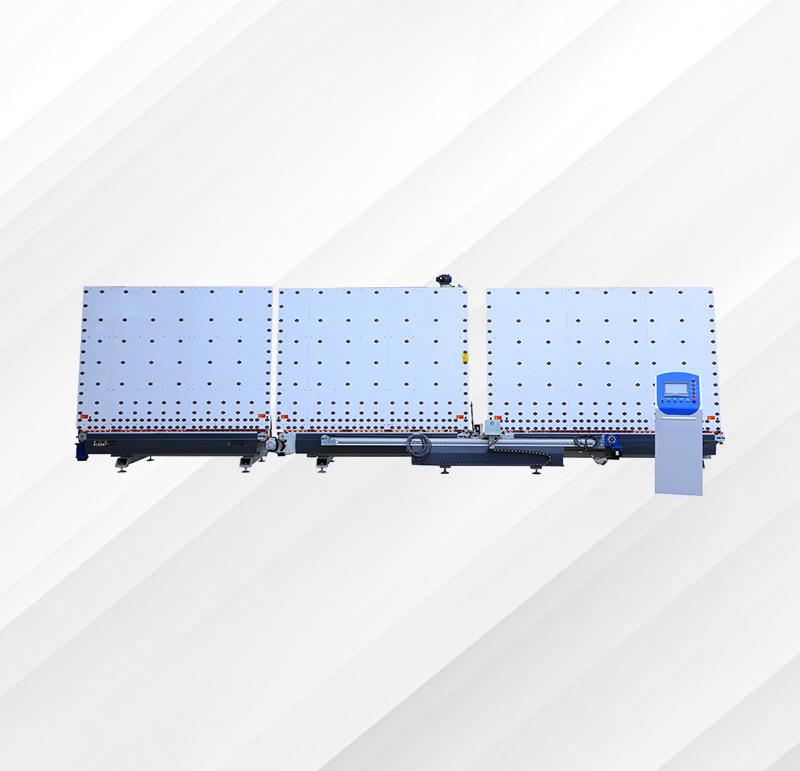

四段均以相同的傾角立式安放,結構緊湊、經濟實用、效率高、維護方便。清洗箱為不銹鋼材料制造,傳送輥為耐酸堿橡膠輥;通過有機玻璃視窗可隨時方便地觀察玻璃清洗情況;

All four sections are vertically placed at the same inclination angle, with a compact structure, economic practicality, high efficiency, and easy maintenance. The cleaning box is made of stainless steel material, and the conveying roller is acid and alkali resistant rubber roller; Through the organic glass window, it is easy to observe the glass cleaning situation at any time;

入料段、清洗干燥段采用手動無級調速電機傳動,玻璃以最佳的速度平穩地運行。

The feeding section and cleaning and drying section are driven by manual stepless speed regulation motors, and the glass runs smoothly at the optimal speed.

干燥段采用大風力傾斜風刀能使玻璃表面得以干燥。

The use of high wind force inclined blades in the drying section can dry the surface of the glass.

檢查段設有燈管,能清晰地檢查玻璃的清洗質量;

The inspection section is equipped with a light tube, which can clearly check the cleaning quality of the glass;

合片段具有玻璃定位及鋁框定位裝置,能完成玻璃定位、鋁框定位安放功能。

The composite segment has glass positioning and aluminum frame positioning devices, which can complete the functions of glass positioning and aluminum frame positioning placement.

玻璃由傳送膠輥承托及傳送,傳送輥由電機(輥壓段電機)經過變頻調速器通過鏈輪帶動,玻璃由清洗干燥段低速進入本段,經檢查合格后加速運行至下一工作段,提高工作效率;由變頻調速器控制本段調速電機的運行速度,光電開關控制玻璃進入下一工作段。

The glass is supported and transported by a conveyor roller, which is driven by a motor (roller pressing section motor) through a frequency converter and a sprocket. The glass enters this section at a low speed from the cleaning and drying section, and after passing the inspection, it accelerates to the next working section to improve work efficiency; The operating speed of the speed regulating motor in this section is controlled by a frequency converter, and the photoelectric switch controls the glass to enter the next working section.

以上就是有關:中空玻璃生產線 的介紹,想了解更多的內容請點擊: http://m.bjrcc.com.cn 我們將會全心全意為您提供滿分服務,歡迎您的來電!

The above is an introduction to the production line of insulated glass. To learn more, please click: http://m.bjrcc.com.cn We will wholeheartedly provide you with full score service. Welcome to call us!

- 中空玻璃丁基膠涂布機突發停電?這樣清洗膠槍,次日正常開工 2026/01/23

- 雙組份打膠機小技巧:黑膠干太快/太慢?這樣調比例就搞定 2026/01/22

- 中空玻璃生產線光電開關小難題:感應不到磨砂玻璃?這樣調就管用 2026/01/20

- 雙組份打膠機旋轉伺服報警810?這樣解決快速恢復生產 2026/01/16

- 中空玻璃加工設備:打膠機機頭升降鏈條松動?這樣調節精準又牢固 2026/01/14

- 中空玻璃生產線合片段橫梁調平指南:小誤差別忽視,這樣調精準又省心 2026/01/12

- 中空玻璃加工設備的合片段橫梁高低不平?這樣調,合片精準不跑偏 2026/01/11

- 中空玻璃加工設備板壓段卡殼?輪子走玻璃不走?這樣排查超高效 2026/01/10

- 中空生產線封膠線機頭立柱不平?這樣調整,封膠均勻不返工 2026/01/05

- 中空玻璃加工設備卡殼?液壓站不起壓?卡閥問題這樣解決超省心 2025/12/31

當前位置:

當前位置:

產品分類Product categories

產品分類Product categories

聯系我們Contact us

聯系我們Contact us